E-mobility

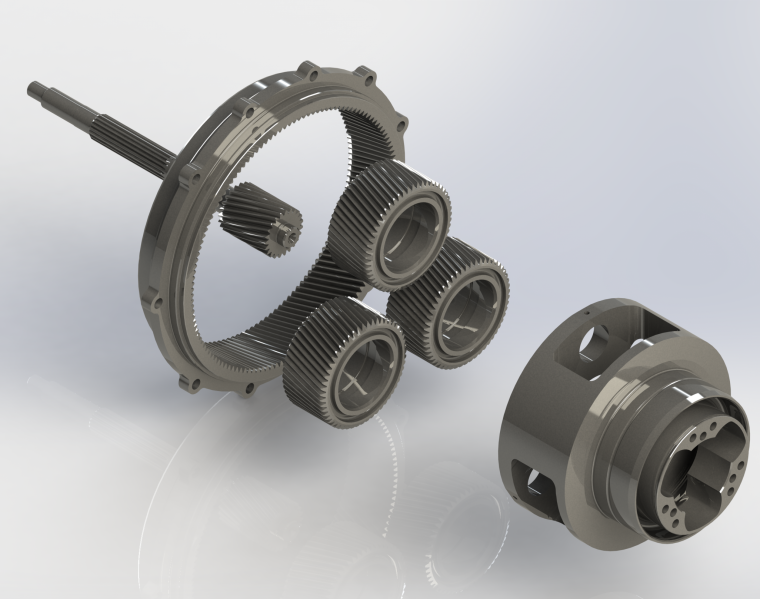

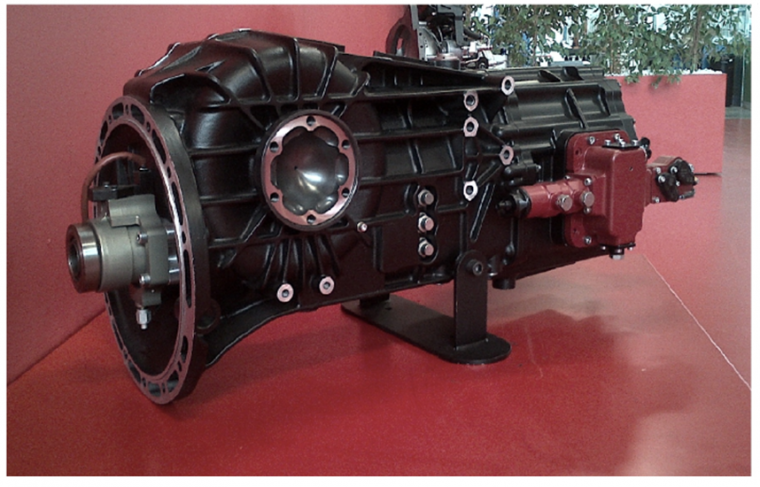

Replacing propulsion methods with electrification does not replace what generates and enables movement: the gears.

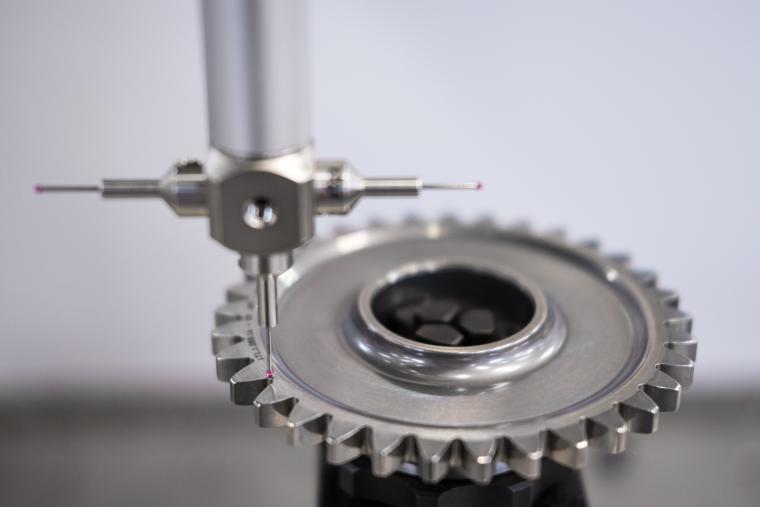

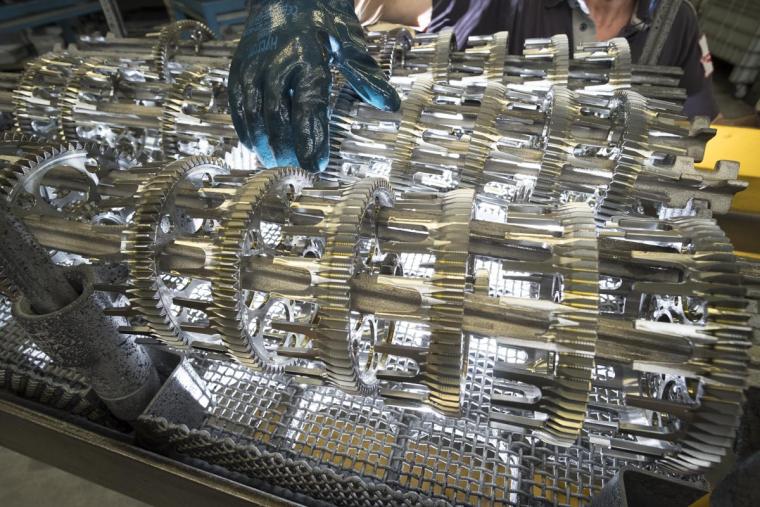

Gears have an impact on torque, and speed, creating the conditions to convert propulsion energy but must meet high standards.

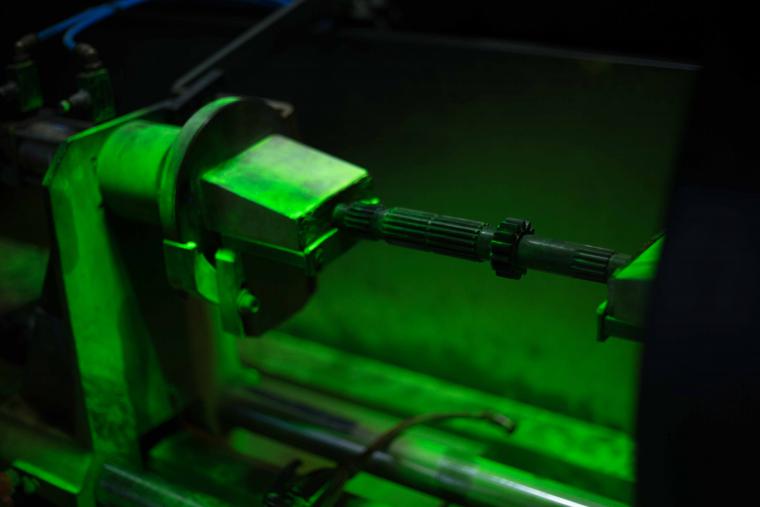

Low noise, lower weight, transmission complexity, and high precision are just some of the challenges that CIMA is ready to address.

We are active in the all-round electric mobility sector: from aerospace to next-generation transmissions for industrial automotive and automotive and electric racing vehicles.