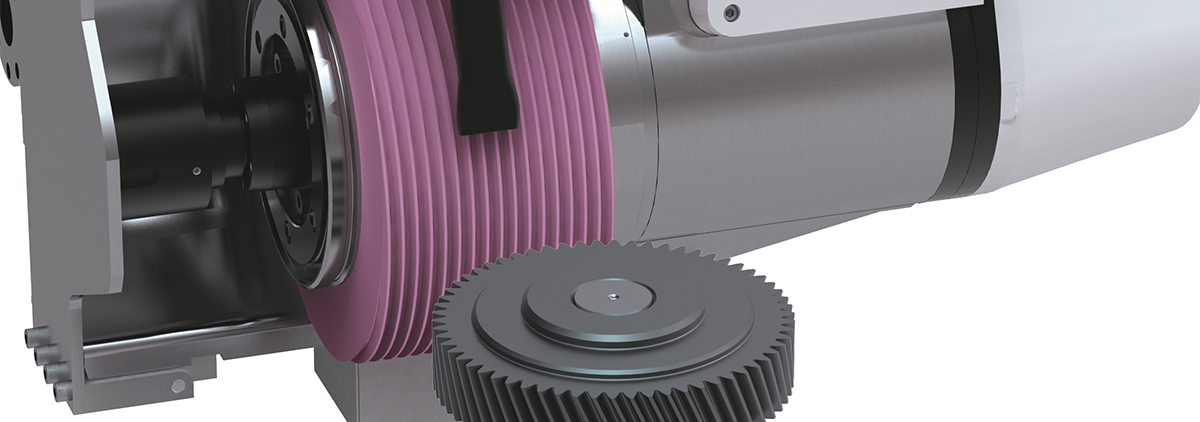

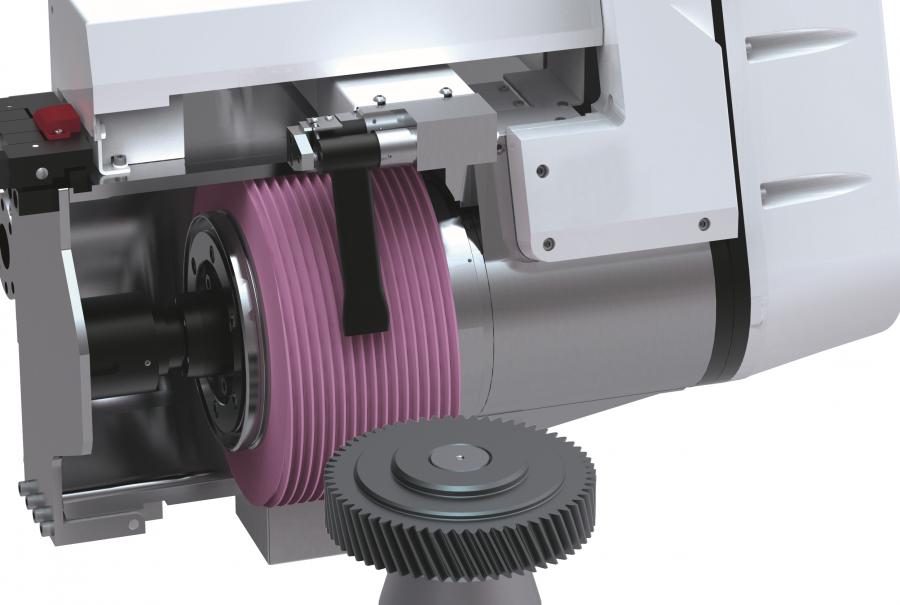

CIMA welcomes the new Reishauer RZ260 4.0: Boosting Gear Production with Advanced Grinding Technology

CIMA has recently elevated its production capabilities with the Reishauer RZ260 4.0, an advanced gear tooth grinding machine that brings new levels of precision and efficiency to gear manufacturing.

This smart technology can handle a wide range of workpieces across various industries, all gears for mechanical application, gears for medium-sized machinery, and other specialized equipment. It offers high production versatility for a broad spectrum of gear sizes, accommodating a maximum diameter of 262mm.

Speed and Productivity

Speed is a critical factor in modern manufacturing, and the RZ260 4.0 excels with a maximum feed speed of 100m/s, ensuring rapid and precise machining. Its innovative dual table design facilitates the seamless loading of one workpiece while another is being machined, thus optimizing productivity, and minimizing downtime.

Control and Precision

Equipped with Siemens 840D SL control software, the RZ260 4.0 offers intuitive operation and precise control over machining parameters. This software suite includes twist control and super finishing grinding features, and innovative grinding wheel/helix profile contact conditions, ensuring superior surface quality and finishing. The grinding wheel can be designed with dual grits, allowing for roughing with a coarser grit and finishing with a finer section, ensuring meticulous attention to detail. Advanced technology and precise control minimize the risk of burns during grinding operations with high-speed feed and optimal grinding conditions, enabling efficient material removal without excessive heat, preserving the integrity of the workpiece, and reducing the likelihood of defects or damage.

Innovative Grinding Technology

One of the machine's standout features is its twist control system, which revolutionizes the contact conditions between the grinding wheel and helix profile. This results in a higher bearing ratio, improved torque transmission, enhanced power density, and greater design flexibility. Additionally, its low noise shifting feature significantly reduces gear noise, contributing to smoother operation and overall improved performance, setting new standards for precision and performance in the industry.

Advanced Features and Capabilities

The Reishauer RZ260 4.0 stands out with its dual grinding options, utilizing both generating grinding wheels and form grinding wheels. This flexibility allows it to achieve teeth modules ranging from 0.5 to 5, further enhanced by a head inclination angle of +/- 48°, accommodating a diverse range of grinding operations and offering versatility for a wide range of gear sizes.

Unmatched Flexibility in Prototyping

When it comes to prototyping, the Reishauer RZ260 4.0 stands out from the competition with its unparalleled flexibility. Thanks to its advanced diamond dresser software, this machine can effortlessly create any gear profile, facilitating rapid iteration and refinement of designs. This powerful capability not only speeds up the development process but also empowers CIMA to swiftly adapt to evolving customer requirements and market demands.

In addition, the RZ260 4.0 excels in point-to-point grinding for special profiles on generating grinding wheels through its linear dressing feature. This enables precise simulation of machining during the prototyping phase, it will also be possible to simulate any errors and work on their correction before moving on to series machining, even without the final dressing wheel tool. By allowing for early detection and correction of potential errors, this approach ensures a seamless transition to series production, maintaining high quality and efficiency throughout.

By incorporating these advanced features, the RZ260 4.0 not only enhances operational efficiency but also boosts productivity, enabling CIMA to deliver superior quality gears faster and more reliably. This strategic investment positions CIMA at the forefront of the gear manufacturing industry, offering customers innovative solutions that meet the highest standards of performance and precision.

If you want to discover more about how CIMA can support your gear production needs, write us at sales@cimaingranaggi.it