Speed starts here: CIMA and Hennessey – engineering the Venom F5

Every hypercar begins with a goal. The Hennessey Venom F5 began with a question: how far can mechanical execution be pushed when the target speed sits beyond 300 mph? Chasing a number like that demands engineering depth, but also the human ability to collaborate, adapt, and make decisions when pushing the boundaries of physics.

That’s the mindset in which CIMA joined the development of this Hennessey Special Vehicles project: not as a supplier ticking requirements, but as a partner invited into a challenge that demanded solutions capable of reaching new levels of performance.

Origins of the CIMA-Hennessey partnership for the Venom F5

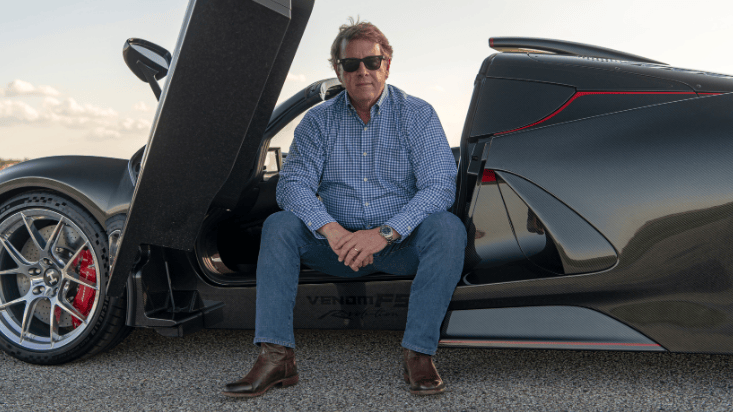

Between 2018 and 2019, the Texas-based hypercar builder was evaluating potential transmission suppliers “…At that point, we were assessing suppliers capable of delivering a gearbox that could handle the unprecedented power of our engine, and CIMA quickly emerged as a serious contender”, stated John Hennessey, company founder and CEO.

Originally, the Venom F5 featured a 6.6-liter twin-turbo V8 delivering 1,817 hp and 1,617 Nm of torque, but now the new ‘Evolution’ model delivers an astonishing 2,031 hp and 1,950 Nm, numbers that push materials, tolerances, and design philosophies to their limits. You don’t start from scratch for this environment; you take a proven foundation and elevate it to meet unprecedented demands. This set the stage for CIMA to begin a dialogue shaped entirely around the car’s unique requirements.

“The Venom F5’s engine produces extraordinary power – it’s the world’s most powerful internal combustion hypercar – so, we needed a gearbox that could reliably manage extreme torque and speed. CIMA’s T1107 transmission proved to be one of the few capable of withstanding the demands, offering the robustness and performance we needed without compromise”, continued Mr Hennessey.

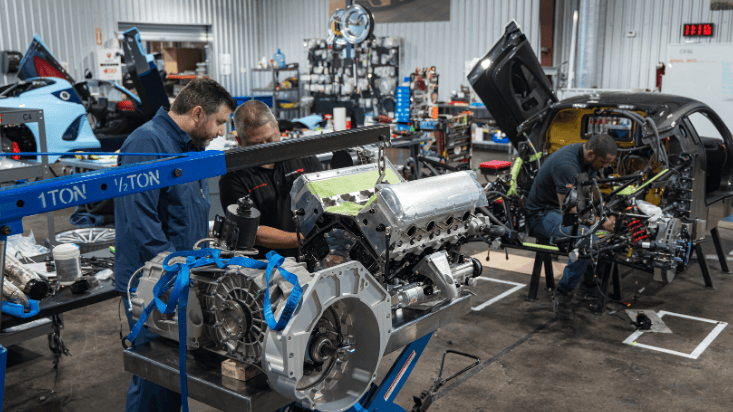

Development of the T1107 transmission for extreme hypercar performance

The T1107 transmission reflects a journey of precision, shaped by dialogue, reimagined details, and moments where teams on opposite sides of the ocean aligned to push a proven design to new heights.

As Hennessey highlights, “The gearbox has enabled us to push the Venom F5 beyond 270 mp during early testing and we’re confident of its capabilities beyond our targeted 300+ mph top speed. It also helped us to set a production car lap record at Circuit of the Americas (COTA), alongside successfully completing multiple high-speed tests”.

Every element — housing, shafts, gear geometry, and final drive — was designed to deliver seamless integration and uncompromising performance in high-speed environments:

- AMT architecture optimized for rapid, consistent shifting

- Compact housing engineered to fit harmoniously within lightweight, high-rigidity structures

- Internal gearing calibrated to handle extreme torque profiles

- Structural components validated for durability under sustained extreme loads

Each element was designed to support the hypercar’s ‘decathlete’ characteristics, top-speed goal, and overall dynamic balance. A project meticulously optimized, culminating in a transmission built to deliver rapid, repeatable shifts under conditions that push metal to its limits and challenge every assumption.

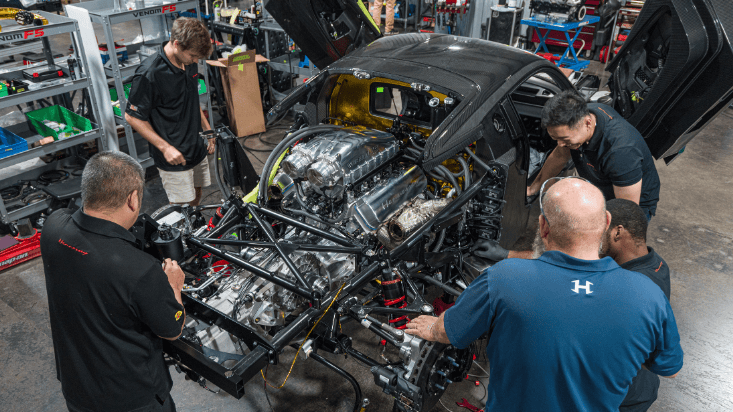

Transmission integration and key engineering challenges

But, often challenges reveal themselves only when you’re already deep into the work. One of the toughest was the custom final drive, a piece that spins at such extreme speeds that even the smallest deviation can undo months of development.

“It was one of the most intense parts of the project.” John and Ryland Hennessey recall, “Designing a final drive that could support the car’s top speed required an exceptional level of precision. Working closely with CIMA allowed us to find solutions quickly.”

Achieving the required precision involved multiple design rounds. There were long sessions of simulations, prototypes tested and re-tested, and combined decision-making. CIMA’s motorsport background provided the knowledge needed to address the challenges and each loop brought the teams closer. Not just technically, but in mindset.

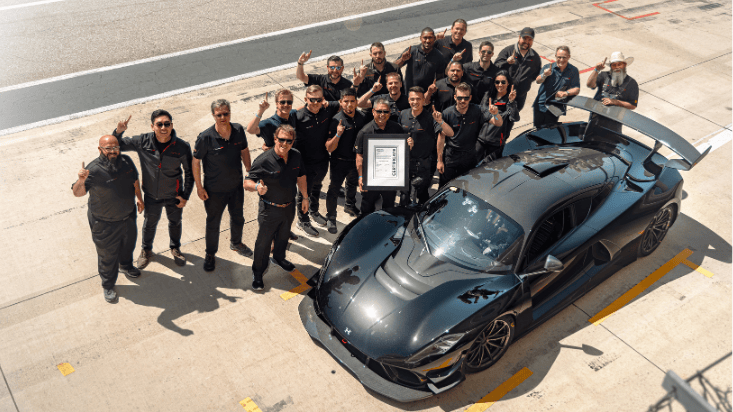

Proving performance where limits disappear

Real-world testing ultimately determines whether an idea works under pressure. The Venom F5’s validation program pushed the T1107 into conditions where materials are strained, temperatures surge, and aerodynamic forces reshape the car’s behavior. And the transmission held.

“The gearbox remained responsive and stable throughout long-duration high-speed sessions.” Hennessey engineering team notes. “It delivered the predictability and control the car needed in extreme conditions.”

During development, the Venom F5 exceeded 270 mph, later securing the production-car lap record at Circuit of the Americas. Long-duration tests at full throttle confirmed that the transmission could sustain extreme loads without degradation — a testament to the decisions made during design and integration.

Not every challenge emerged in simulations. Thermal expansion behaved unpredictably. Efficiency shifts occurred at high load. These issues were resolved through shared expertise, and the willingness of both teams to refine until everything worked exactly as intended.

The result was more than a functional transmission — it was a demonstration of what two teams can achieve when they solve problems side by side.

CIMA’s strategic role in future high-performance transmission engineering

As development moved forward, collaboration became just as crucial as engineering precision. Challenges emerged, decisions were shared quickly, and both teams worked with a clarity that kept the program advancing even under pressure. It was a dynamic built on trust and technical discipline — something John and Ryland Hennessey later described simply as, “an incredibly positive partnership built on technical competence and a willingness to go the extra mile”. That experience continues to shape the relationship today: the Venom F5-M is powered by a manual six-speed evolution of the original gearbox, and CIMA is already being considered for future Hennessey programs.

The Venom F5 shows how ambitious performance goals can be achieved when superior engineering meets close collaboration. The T1107 enabled Hennessey to manage extraordinary engine output with stability and control at extreme speeds.

Curious to see what else can happen when teams work this closely? Explore CIMA’s ongoing collaborations across hypercars, motorsport and advanced mobility.